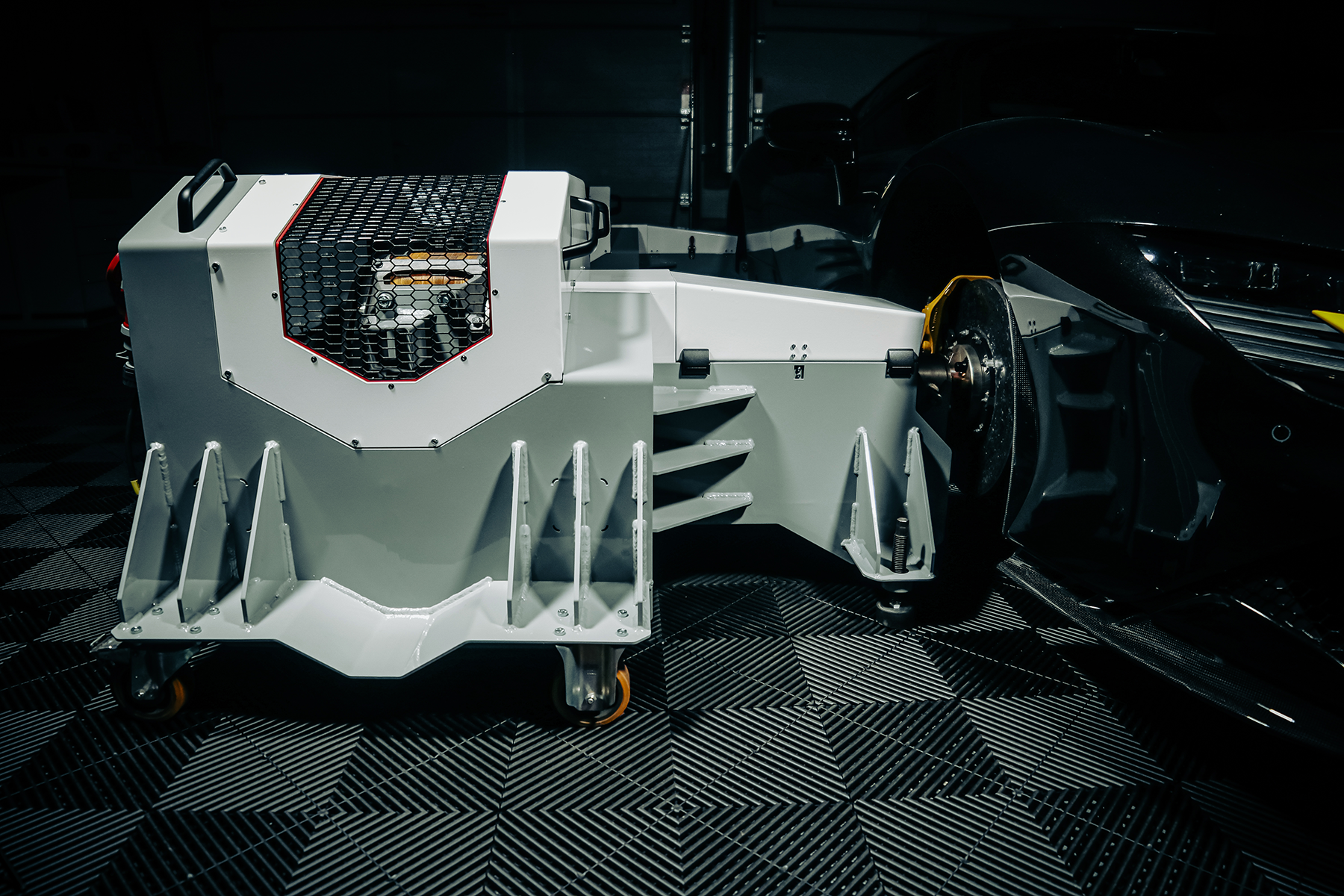

After 27 months of research and development, our engineers in Jihlava, the industrial heart of Europe, have brought a true evolutionary innovation to the field of Automotive Metrology. It is a passive simulator that is directly attached to the drive hub of the system.

We have achieved a real milestone in solving applications where it is absolutely critical to understand the behaviour of the drivetrain and transmission in the Automotive and Motorsport industries. The repeatability, accuracy and reproducibility of the data obtained in this industry has never been at such a maximum level as in the case of the W series.

The vision leading up to the launch of the W series project and its successful completion was to develop metrology equipment that would completely change the way testers look at test benches and offer professionals possibilities that were previously only possible in their minds. By integrating know-how and maximum concentration of science, we have introduced a device for the most prestigious applications that is currently unrivalled", says Jakub Klobasa, ATX-Implements CEO.

The future belongs to ATX-Dyno dynamometers. Expertise, precision workmanship and quality are the essential attributes of this rising star.

Modular System

The modularity of the W-series system is absolute. Configure your test bench exactly to your needs – stack 2WD and 4WD combinations, assign different braking power to each axle. Perfect for hybrid and e-motion applications. Advanced AI ensures full synchronization or individual tasking as needed.

Don't Be Disturbed

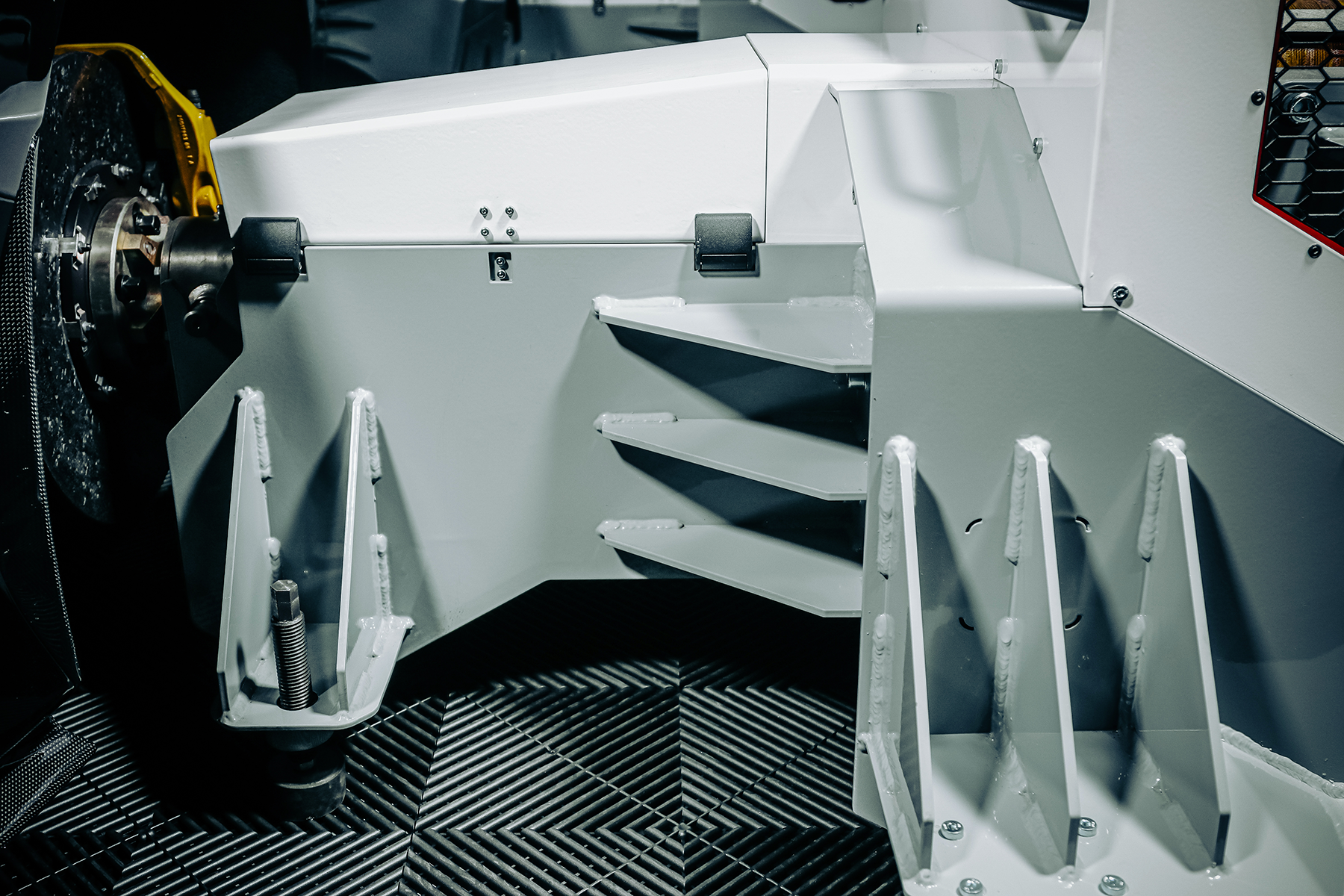

Conventional vehicle testing suffers from frictional loss, tire heating, and suspension deformation. The W-series eliminates these influences entirely. Direct drive hub connection removes typical testing limitations and ensures measurement accuracy you can rely on—without distraction.

Smart Control

The W-series features intelligent software architecture with advanced ECU and control electronics. It ensures precise, intuitive data acquisition in both dynamic and static modes—no compromises, just clarity and power at your command.

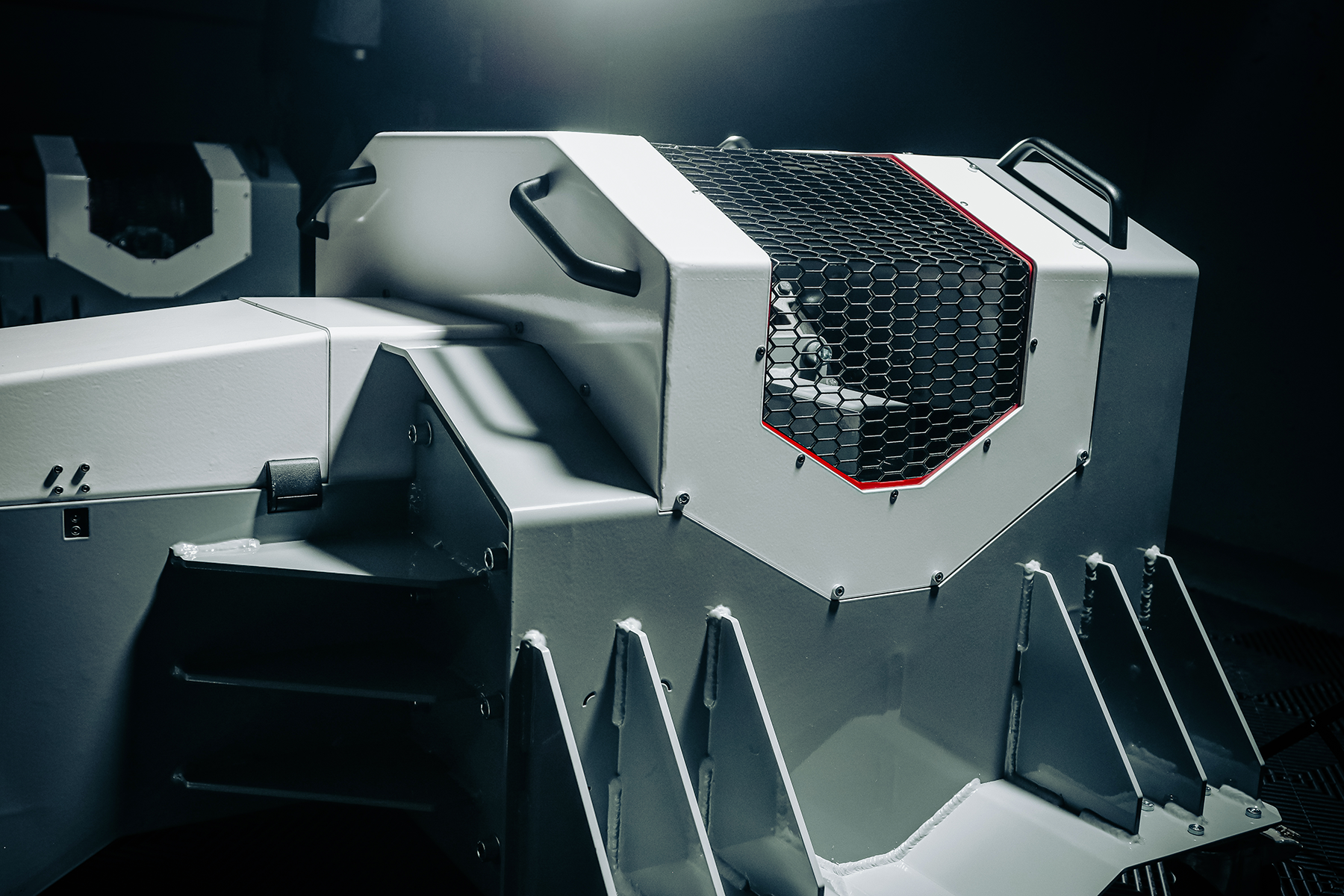

Crafted to Perfection

The W-series dynamometers are made only from top-tier components. Each element is precisely where you'd expect it—flange sets, control boxes, access holes, frame, handling features and more. Even external ducting options are built-in for lab or chamber operations.

Foldable

From test lab to fieldwork—W-series dynamometers adapt. Easily deployable in mobile or semi-permanent setups. Perfect for users without space for a full-time workshop. Precision, anytime, anywhere.

Technical specification

W2.1 |

W2.2 |

W2.3 |

|

| Performance [kW] | 350 | 500 | 750 |

| Torque [Nm] | 3 000 | 4 500 | 6 600 |

| Cardan shaft | EXTRA load, high-speed, transmisible torque = 5 kNm | ||

| Power [V]/[A]: | 3x230/32 | 3x230/32 | 3x230/32 |

| Mass [kg]/per module: | 568 | 752 | 876 |

| Performance cell: | 2x EDDY-current dyno retarder P5 | 2x EDDY-current dyno retarder P7 | 2x EDDY-current dyno retarder P10 |

| Performance flow: | 4x radial fan 405 mm | 4x radial fan 460 mm | 4x radial fan 550 mm |

W4.1 |

W4.2 |

W4.3 |

|

| Performance [kW] | 700 | 1000 | 1500 |

| Torque [Nm] | 6 000 | 9 000 | 13 200 |

| Cardan shaft | EXTRA load, high-speed, transmisible torque = 5 kNm | ||

| Power [V]/[A]: | 3x230/32 | 3x230/32 | 3x230/32 |

| Mass [kg]: | 1136 | 1504 | 1752 |

| Performance cell: | 4x EDDY-current dyno retarder P5 | 4x EDDY-current dyno retarder P7 | 4x EDDY-current dyno retarder P10 |

| Performance flow: | 8x radial fan 405 mm | 8x radial fan 460 mm | 8x radial fan 550 mm |

Accessories |

|||

| OBD WiFi hub | |||

| TV | |||

| Multimedia packet | |||

| External sensors | |||

| Ventilation system | |||